Automotive Parts

Automotive Parts Solutions By Casting &Cnc Machining

IATF 16949 CERTIFIED CAST MANUFACTURING AND CNC MACHINING FOR AUTOMOTIVE PARTS

As the foundation of the auto industry, auto parts are necessary factors to support the sustainable and healthy development of the auto industry. In particular, the current independent development and innovation of the auto industry is developing vigorously and in full swing, and it needs a strong parts system to support it. Major auto parts manufacturers have applied aerospace, aviation and electronics technologies to auto parts and assemblies. Safety technology, electronic technology, energy-saving technology and environmental protection technology have been widely used in automobiles. In particular, new technologies represented by electronic information technology are not only widely used in automotive products, but also extend to various aspects such as development and design, trial production, production and management; not only applied to individual auto parts, but also applied System assembly.

Vehicle independent brands and technological innovation require parts and components as the foundation. Independent innovation of parts and components has a strong driving force for the development of the vehicle industry. They influence and interact with each other. There is no independent brand of complete vehicles, and a strong parts system The R&D and innovation capabilities of the company are difficult to burst. Without the support of a strong parts system, it will be difficult for independent brands to become bigger and stronger.

Do you need automotive parts custom from die casting?

As a TS 16949-certified manufacturer, Minghe has been involved in the field of machining and die casting automotive parts. Our skilled personnel spare parts staff can supply you using a quotation for that precise element you need for the china or even overseas create a car. The good news is a great range of car spare parts, as well we have good quality and low cost auto parts pertaining experience to foreign creates of motor vehicles, such as Toyota, Mazda plus Hyundai.Request a FREE quote today.

Contact our automotive part engineer today to discuss the specifics of your complex projects.

1.Commonly Automotive Components Applications.

MINGHE’s experience is unrivaled in the design, development, and manufacture of precision die cast and cnc machining solutions for a wide range of automotive applications, including but not limited to:

- Engine Accessories: throttle body, engine, engine assembly, fuel pump, fuel nozzle, tensioner, cylinder block, bearing bush, water pump, fuel injection, gasket, camshaft, valve, crankshaft, connecting rod assembly, piston, belt, Muffler, carburetor, fuel tank, water tank, fan, oil seal, radiator, filter

- Powertrain Accessories: transmission, gear shift lever assembly, reducer, clutch, pneumatic, electric tools, magnetic materials, electronic components, clutch disc, clutch cover, universal joint, universal ball, universal ball, ball Cage, clutch plate, transfer case, power take-off, synchronizer, synchronizer ring, timing belt, differential, differential case, differential disc angle teeth, planetary gear, wheel carrier, flange, gear box , Intermediate shaft, gear, gear lever fork, drive shaft assembly, drive shaft flange, belt

- Brake System Accessories: brake shoes, brake pads, brake discs, brake drums, compressors, brake assemblies, brake pedal assemblies, brake master cylinders, brake cylinders, ABS-ECU controllers, electric hydraulic pumps, Brake camshaft, brake roller, brake tellurium pin, brake adjustment arm, brake chamber, vacuum booster, hand brake assembly, parking brake assembly, parking brake operating lever assembly

Steering system accessories: steering gear, steering knuckle ball joint, steering knuckle steering wheel, steering gear, assembly booster, steering tie rod, power pump... - Walking Accessories: rear axle, air suspension system, balance weight, steel plate, tire, leaf spring, half axle, shock absorber, steel ring assembly, half axle bolt, axle housing, frame, assembly, wheel platform, Front bridge

Electrical instrumentation accessories: sensors, automotive lamps, buzzers, spark plugs, batteries, wiring harnesses, relays, audio, alarms, regulators, distributors, starters (motors), unidirectional devices, automotive instruments, switches, fuse , Glass lifter, generator, ignition coil, igniter thermostat, ignition module - Automotive Lamps: decorative lights, headlights, searchlights, ceiling lights, anti-fog lights, instrument lights, brake lights, tail lights, turn lights, emergency lights

- Car Modification: tire pumps, car roof racks, car roof boxes, electric winches, car buffers, sunroofs, sound insulation materials, bumpers, fixed wind wings, fenders, exhaust pipes, fuel economy

- Security And Anti-theft: steering wheel lock, wheel lock, anti-theft device, rear view mirror, rear view system, camera, seat belt, driving recorder, central control lock, GPS, ABS, reversing radar, gear lock

- Car Interior: car carpet (foot pad), steering wheel cover, steering wheel booster ball, curtains, sun gear...

- Car Exterior: wheel cover, body color stripe sticker, license plate holder, rain and rain cover.. tire pressure monitoring system, decoder, display, car intercom...

- Body And Accessories: wiper, car glass, seat belt, airbag, instrument panel, static elimination antenna static belt...

- Maintenance Equipment: sheet metal equipment purification system, tire changer corrector...

- Power Tools: electric punch, hot air gun, electric jack, electric wrench...

2.Why Choose Us For Your Automotive Parts Projects

Minghe has over 30 years of experience assisting automotive manufacturers design cost-effective automotive components. When you partner with Minghe you can receive the following benefits from our die casting process:

- Minghe’s die casting operation features 40 presses ranging from 250 to 3000 ton. We accommodate some of the most demanding automotive part runs in terms of volume, part size, and complexity. Because of our engineering and modeling capabilities, we are known by our clients as a company that can reduce part complexity, and make the manufacturing process more efficient.

- Minghe can help consolidate your supply chain by offering the complete package of die casting services in addition to engineering support, mold design and troubleshooting, machining, and logistics.

- Minghe is an ISO Certified Die Casting Manufacturer and has extensive experience in designing and manufacturing zinc and aluminum parts to automotive quality specifications.

- With presses ranging from large to small, we have the capability to manufacture automobile parts of all sizes, from a valve cover to large housings for trucks.

- We are ITAF 16949 certified and can provide part manufacturing for military and aerospace applications.

- Our technology facilitates and streamlines production. Our suite of technology includes AutoCAD, Pro-E, MAGMAsoft®, CAD/CAM and EDI compatibility, and FARO Laser Scanning.

3.Commonly Used Materials For Custom Automotive Parts By Die Casting

Minghe has the expertise to help you choose the right alloy for the application if needed. We utilize a wide range of alloys to meet specifications of temperature, use, and strength. Some of our commonly used aluminum and zinc-aluminum alloys include AL360, AL380, AL383, and AL413, ZA-8, ZA-12, ZA-27. We also provide casting services using K-Alloy. In addition to a variety of alloys, PHB offers finishing services including powder coating, wet paint, shot bead blasting, EMI/RFI shielding, chrome, and more.

4.Other Manufacturing Service For Custom Automototive Parts

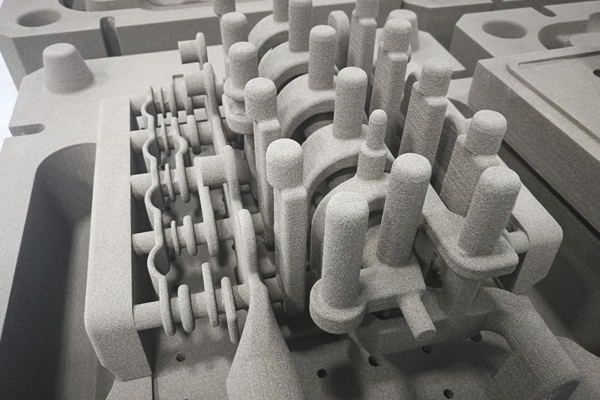

In addition, Minghe also provides CNC machining, investment casting, sand casting and other services related to customized auto parts.

| Cnc Machining Automotive Parts |

|

| Investment Casting Automotive Parts |

|

| Sand Casting Automotive Parts |

|

5.Capabilities of Our Precision Manufacturing for Automotive Parts

In addition, Minghe also provides CNC machining, investment casting, sand casting and other services related to customized auto parts.

AL360, AL380, AL383, and AL413, ZA-8, ZA-12, ZA-27,Aluminium A356,

Black, White, Silver, Red, Natural, Blue, Green and different colors as client requirements

Sand blasting, shot blasting, polishing, anodizing, oxidation, electrophoresis, chromate, powder coating and painting

Die Casting,Mold Manufacturing,CNC milling, CNC turning, CNC drilling

Interior panels, Die molds, Drive trains, Pistons, Camshafts, Turbo chargers, Aluminum wheels, Starter motors, Cylinder heads, Drive axles, Gearboxes, Custom parts and Prototyping Applications

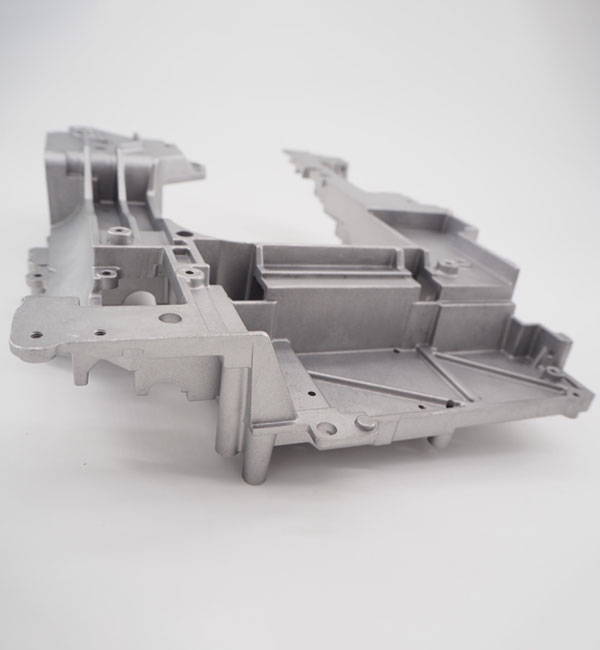

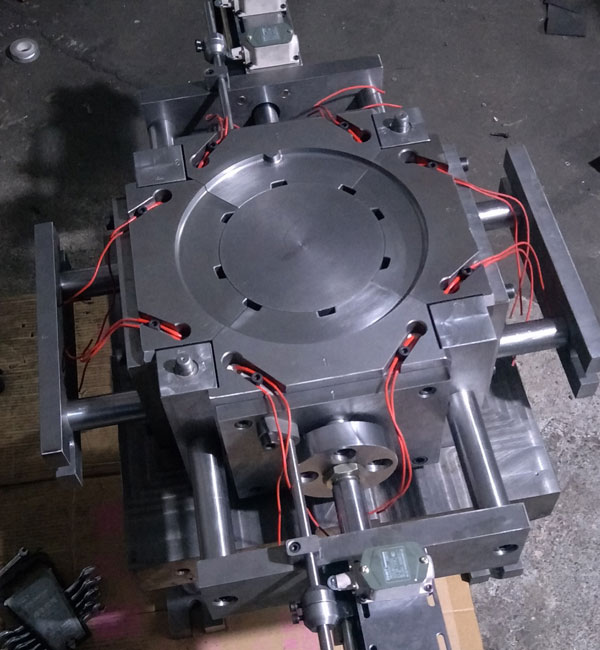

The Minghe Case Studies Of Automotive Parts

You have a complex part design, Minghe Casting Company can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Minghe Casting ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

Go To View More Casting Parts Cases Studies >>>

Choose the Best Automotive Parts Casting Service

Currently, our automotive parts casting and machining parts are exported to America, Canada, Australia, United Kingdom, Germany, France, Sout Africa, and many other countries all over the world. We are ISO9001-2015 registered and also certified by SGS.

Custom china die casting service provides durable and affordable castings that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, marine, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.Contact us or Email sales@hmminghe.com to see how our people, equipment and tooling can bring the best quality for the best price for your automotive parts casting project.

We Provide Casting Services Include:

Minghe Casting services working with sand casting、metal casting 、investment casting lost foam casting, and more.

Sand Casting

Sand Casting is a traditional casting process that uses sand as the main modeling material to make molds. Gravity casting is generally used for sand molds, and low-pressure casting, centrifugal casting and other processes can also be used when there are special requirements. Sand casting has a wide range of adaptability, small pieces, large pieces, simple pieces, complex pieces, single pieces, and large quantities can be used.

Permanent Mold Casting

Permanent Mold Casting have a long life and high production efficiency, not only have good dimensional accuracy and smooth surface, but also have higher strength than sand castings and are less likely to be damaged when the same molten metal is poured. Therefore, in the mass production of medium and small non-ferrous metal castings, as long as the melting point of the casting material is not too high, metal casting is generally preferred.

Investment Casting

The biggest advantage of investment casting is that because investment castings have high dimensional accuracy and surface finish, they can reduce machining work, but leave a little machining allowance on the parts with higher requirements. It can be seen that the use of investment casting method can save a lot of machine tool equipment and processing man-hours, and greatly save metal raw materials.

Lost Foam Casting

Lost foam casting is to combine paraffin wax or foam models similar to the casting size and shape into model clusters. After brushing and drying refractory coatings, they are buried in dry quartz sand for vibration modeling, and poured under negative pressure to gasify the model. , The liquid metal occupies the position of the model and forms a new casting method after solidification and cooling.

Die Casting

Die casting is a metal casting process, which is characterized by applying high pressure to the molten metal using the cavity of the mold. Molds are usually made of higher-strength alloys, and this process is somewhat similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. Minghe has been China's top die casting service since 1995.

Centrifugal Casting

Centrifugal Casting is a technique and method of injecting liquid metal into a high-speed rotating mold, so that the liquid metal is centrifugal motion to fill the mold and form a casting. Due to the centrifugal movement, the liquid metal can fill the mold well in the radial direction and form the free surface of the casting; it affects the crystallization process of the metal, thereby improving the mechanical and physical properties of the casting.

Low Pressure Casting

Low Pressure Casting means that the mold is generally placed above a sealed crucible, and compressed air is introduced into the crucible to cause a low pressure (0.06~0.15MPa) on the surface of the molten metal, so that the molten metal rises from the riser pipe to fill the mold and control Solidified casting method. This casting method has good feeding and dense structure, easy to cast large thin-walled complex castings, no risers, and a metal recovery rate of 95%. No pollution, easy to realize automation.