Case Studies

Manufacturing Process

Parts Material

Application Industry

Surface Treatment

Invest casting Stainless Steel 316304 Glass Claw Parts

Invest casting Stainless Steel 316304 Glass Claw Parts;Currently, our investment casting foundry covers an area of 20,000 square meters. There are total 245 workers in our factory, with 205 workers, 5 engineers, 23 QC man, 7 sales person, and 5 management.

Investment Casting Stainless Steel 304 Food Machinery Parts

We are OEM Investment Casting Stainless Steel 304 Food Machinery Parts supplier in China. We manufacture high-precision components from metals. we have both casting foundry & machining factory.

Stainless Steel Handrail Pipe Joint And Pipe Fitting ALSI12

Stainless Steel Handrail Pipe Joint And Pipe Fitting ALSI12Withmodern,reasonable,strictly process,our Major service include part design, mold design, mold flow analysis, mold manufacture, ,diecasting and secondary process,our parts include electrics, automotive, medical part, mechanical part,home appliance.Wemade hign quality and low price precision die casting mold with advanced manufacture equipment and depth designexperience,90% mold are exported to USA,Germany,France,etc

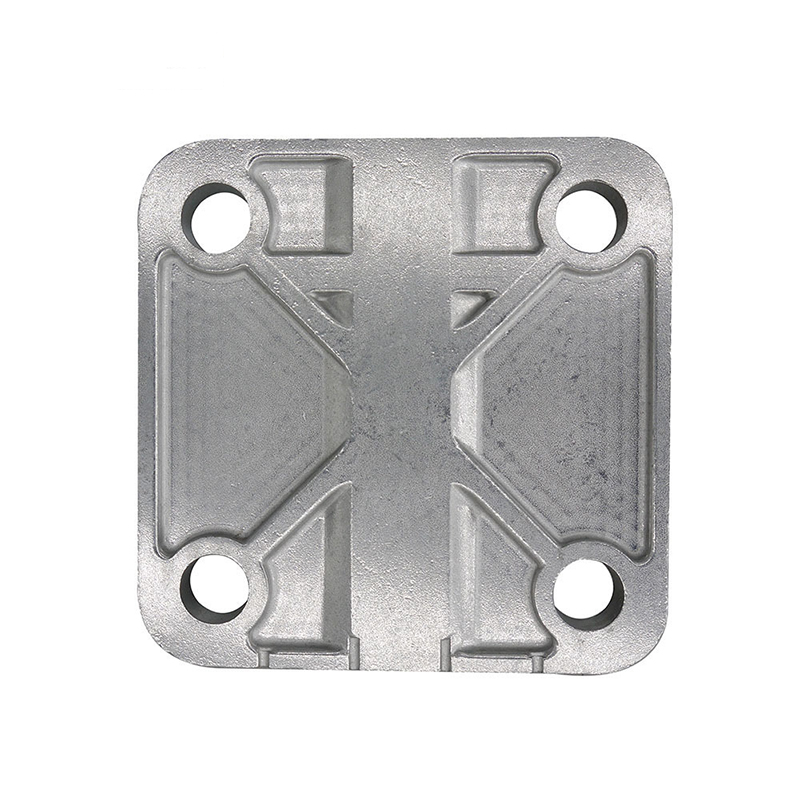

Aluminum Die-Cast Bench Chair Leg Parts Used For Park

For Die-Cast Bench Chair Leg Parts, post-machining can be totally eliminated, or very light machining may be required to bring dimensions to size. die casting,aluminum casting can be done using a cold chamber or hot chamber process.

Customized Stainless Steel Investment Casting Motorcycle Crankshaft

Lost wax casting process can be used to cast products with weights range from 0.1-100kgs, with max sizes at 500*600mm, and wall thickness between 2-50mm.

OEM Aluminum Die-Casting Bearing Cap China

Over the years, we have exported a variety of OEM Aluminum Die-Casting Bearing Cap to customers including public companies such as GE and Voith. We strive to maintain high quality standard and provide cost savings to customers. Depending on your application we can support die casting (hot chamber/ cold chamber), low pressure casting, forging, machining as well as surface finishing.

Gray Iron HT250 Sand Casting Mud Pump Shell

Minghe’s foundry Regal Cast, is able to pour various sand castings, including but not limited to impellers, diffusers, propellers, housings, pump casings, and valve bodies. These quality sand castings are destined for defense, nuclear, industrial and other commercial applications.Variety in alloys, weights (up to 12,000 pounds), and shapes are huge factors in PRL’s sand casting services.

MingHe Casting Advantage

- Comprehensive Casting design software and skilled engineer enables sample to be done within 15-25 days

- Complete set of inspection equipment & quality control makes excellent Die Casting products

- A fine shipping process and good supplier guarantee we can always deliver Die Casting goods on time

- From prototypes to end parts, upload your CAD files, fast and professional quote in 1-24 hours

- Wide-ranging capabilities for designing prototypes or massive manufacturing end use Die Casting parts

- Advanced Die Casting techniques (180-3000T Machine,Cnc Machining, CMM) process a variety of metal & plastic materials

HelpFul Articles

How To Calculate Pressure Die Casting Tonnage

Calculation Formula The calculation formula for the selection of die-casting machine: Die-casting m

The Numerical Control Cutting Process Of Thread

The thread cutting process depends on the structure of the machined parts and the CNC machine tool u

Approximate Fitting And NC Machining Of Ellipse Gear

Oval gears are widely used in automatic machinery and instrument industries, and are a type of non-c

The Role And Application Field Of The Cylinder Telescopic Sheath

The cylinder telescopic sheath is a protective component that is installed on the oil cylinder, cyli

The Wavelet Analysis Of Overcut In Free-Form Surfaces CNC Machining

The manufacturing cycle is long. Operators are prone to fatigue. Once a failure occurs, it often tak

Using pure oxygen burner to reduce energy consumption of ladle preheating

The Wu Steel Works has two workshops, one steelmaking workshop and the second steelmaking workshop.