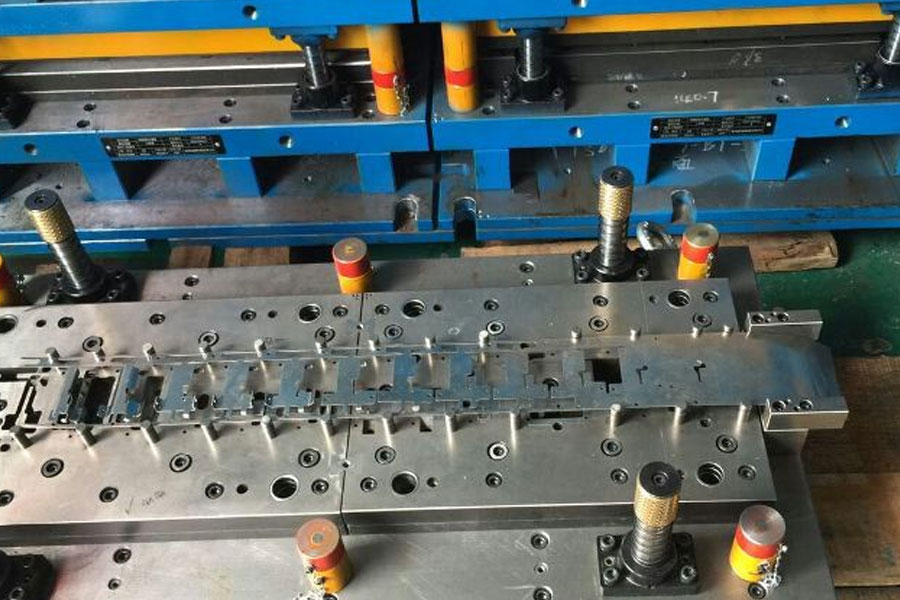

5 Major Links Need To Be Controlled To Improve Mold Life

Including mold production plan formulation, mold design, process formulation, workshop task assignment and product inspection, warehouse management, etc., so that mold manufacturing and related auxiliary information can be fully tracked and managed from planning to completion and delivery. ...