Plastical Forming Method Of Magnesium Alloy

Due to its high production efficiency, low cost, and the ability to produce products with more complex shapes, the casting molding process has a good liquid filling ability and occupies a dominant position in the magnesium alloy molding method. However, due to the production process of cast magnesium alloys, the structure is not dense enough, and there are many defects such as shrinkage porosity and shrinkage cavity, and the mechanical properties are poor. Magnesium alloy products manufactured through plastic machining processes such as extrusion, forging, rolling, etc., have a denser structure and can well improve the mechanical properties of magnesium alloy products. At present, due to the lack of efficient and low-cost magnesium alloy plastic machining methods, the application of magnesium alloy plastic machining is limited. Therefore, the development of high-efficiency and low-cost magnesium alloy plastic machining methods has become the only way to promote the large-scale application of high-strength magnesium alloys. Magnesium alloys mainly have the following plastic machining techniques:

Forged

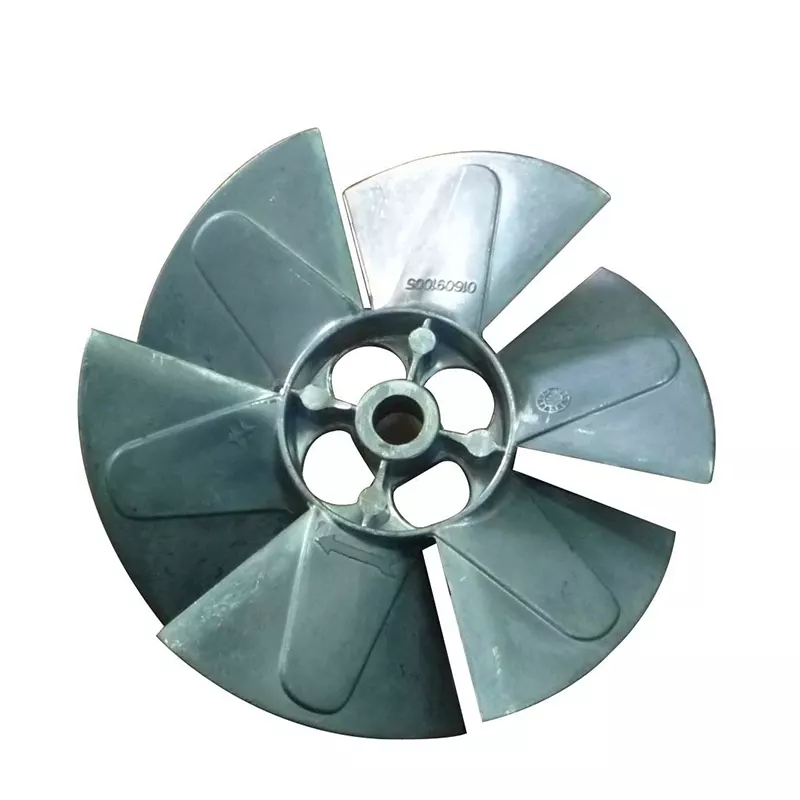

The forging process of magnesium alloys is more complicated. During the forging process, local deformation is prone to unevenness, so that the properties and structure of the workpiece will also be uneven. Mg-Zn-Zr series and Mg-Al-Zn series are commonly used forged magnesium alloys. When there are higher requirements for the strength of materials at higher temperatures, the strength of magnesium alloys with rare earth elements added to the WE series can easily meet the requirements. During the forging process, the degree of deformation, the final forging temperature, and the way of deformation are the main factors affecting the mechanical properties of magnesium alloy forgings. At present, it has mainly developed forming technologies such as punch forging, isothermal forging, and warm precision forging.

Extrusion Molding

Extrusion molding is a plastic machining method in which a metal blank to be formed is placed in a closed extrusion cylinder and a certain pressure is applied to the blank to deform the material in the extrusion die. Since the metal blank is in a three-dimensional compressive stress state during the forming process, the plasticity of the metal blank can be fully exerted in the forming method. Extruded products have good surface quality, high dimensional accuracy, and compact structure. Therefore, magnesium alloy extrusion products are in large demand in the automotive, aerospace, and electronics fields. Generally, the extrusion of magnesium alloy can be divided into hot extrusion and warm extrusion, and the equipment used is basically the same as that of other metal materials.

Roll Forming

Magnesium alloy sheet has broad application prospects in the aerospace and automotive 3C industries due to its unique advantages. Most of the magnesium alloy sheets currently in use are formed by rolling. However, the rolling forming process of magnesium alloy sheet is more complicated, and usually requires 3 or more passes of hot rolling. Magnesium alloy sheet rolling has the following characteristics: low yield, low production efficiency, large profits, and relatively single varieties.

Stamping And Forming

The stamping process of magnesium alloys is different from other materials. Magnesium alloys have low plasticity at room temperature. Conventional cold stamping forming is not suitable for magnesium alloys. Magnesium alloys usually need to be heated to 150°C or higher to perform hot stamping forming. At present, the hot stamping of magnesium alloys has been studied to a certain extent, but its key problems have not been well solved, which to a certain extent hinders the wide application of magnesium alloy sheets in industry.

Draw Forming

In the process of drawing and forming of magnesium alloy, the material is in a state of stress under tension and compression in both directions. At this time, the plasticity of the material is difficult to exert. Therefore, drawing is not suitable for the forming of magnesium alloy. The drawn products have the characteristics of high surface roughness and good dimensional accuracy. Wire and pipe are produced by drawing and forming process, which has high production efficiency and is easy to realize high-speed and continuous production. And the strength of the magnesium alloy wire formed by drawing is higher.

Superplastic Forming

The superplastic forming process can be used to process workpieces with complex shapes and large deformations. It is a metal characteristic that exceeds the general plasticity index under certain conditions. Therefore, superplastic forming can be used to process magnesium alloy products with poor plasticity. However, since the research on superplastic forming of magnesium alloys has just started, there are many problems. It is difficult to reach a consensus on the superplastic deformation mechanism of magnesium alloys. The superplastic forming of magnesium alloys needs further research.

Please keep the source and address of this article for reprinting: Plastical Forming Method Of Magnesium Alloy

Minghe Die Casting Company are dedicated to manufacture and provide quality and high performance Casting Parts(metal die casting parts range mainly include Thin-Wall Die Casting,Hot Chamber Die Casting,Cold Chamber Die Casting),Round Service(Die Casting Service,Cnc Machining,Mold Making,Surface Treatment).Any custom Aluminum die casting, magnesium or Zamak/zinc die casting and other castings requirements are welcome to contact us.

Under the control of ISO9001 and TS 16949,All processes are carried out through hundreds of advanced die casting machines, 5-axis machines, and other facilities, ranging from blasters to Ultra Sonic washing machines.Minghe not only has advanced equipment but also have professional team of experienced engineers,operators and inspectors to make the customer’s design come true.

Contract manufacturer of die castings. Capabilities include cold chamber aluminum die casting parts from 0.15 lbs. to 6 lbs., quick change set up, and machining. Value-added services include polishing, vibrating, deburring, shot blasting, painting, plating, coating, assembly, and tooling. Materials worked with include alloys such as 360, 380, 383, and 413.

Zinc die casting design assistance/concurrent engineering services. Custom manufacturer of precision zinc die castings. Miniature castings, high pressure die castings, multi-slide mold castings, conventional mold castings, unit die and independent die castings and cavity sealed castings can be manufactured. Castings can be manufactured in lengths and widths up to 24 in. in +/-0.0005 in. tolerance.

ISO 9001: 2015 certified manufacturer of die cast magnesium, Capabilities include high-pressure magnesium die casting up to 200 ton hot chamber & 3000 ton cold chamber, tooling design, polishing, molding, machining, powder & liquid painting, full QA with CMM capabilities, assembly, packaging & delivery.

ITAF16949 certified. Additional Casting Service Include investment casting,sand casting,Gravity Casting, Lost Foam Casting,Centrifugal Casting,Vacuum Casting,Permanent Mold Casting,.Capabilities include EDI, engineering assistance, solid modeling and secondary processing.

Casting Industries Parts Case Studies for: Cars, Bikes, Aircraft, Musical instruments, Watercraft, Optical devices, Sensors, Models, Electronic devices, Enclosures, Clocks, Machinery, Engines, Furniture, Jewelry, Jigs, Telecom, Lighting, Medical devices, Photographic devices, Robots, Sculptures, Sound equipment, Sporting equipment, Tooling, Toys and more.

What Can we help you do next?

∇ Go To Homepage For Die Casting China

→Casting Parts-Find out what we have done.

→Ralated Tips About Die Casting Services

By Minghe Die Casting Manufacturer |Categories: Helpful Articles |Material Tags: Aluminum Casting, Zinc Casting, Magnesium Casting, Titanium Casting, Stainless Steel Casting, Brass Casting,Bronze Casting,Casting Video,Company History,Aluminum Die Casting |Comments Off