Steel Materials And Characteristics For Common Machining

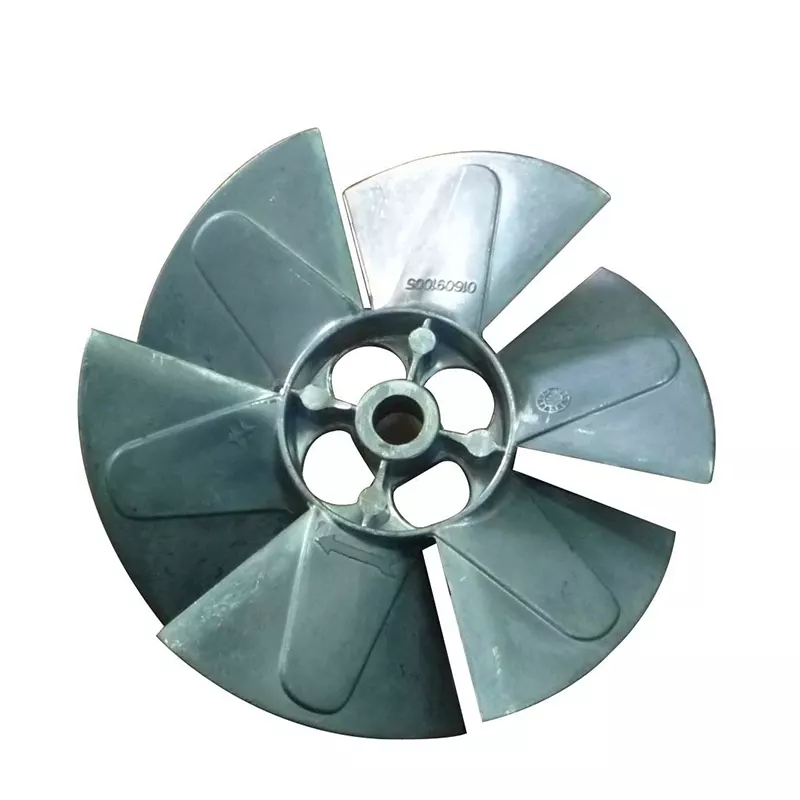

- 1. 45-high-quality carbon structural steel, the most commonly used medium-carbon quenched and tempered steel. Main features: The most commonly used medium carbon quenched and tempered steel, with good comprehensive mechanical properties, low hardenability, and easy to crack during water quenching. Small parts should be quenched and tempered, and large parts should be normalized. Application examples: Mainly used to manufacture high-strength moving parts, such as turbine impellers and compressor pistons. Shafts, gears, racks, worms, etc. Pay attention to preheating before welding and annealing for stress relief after welding.

- 2. Q235A (A3 steel)-the most commonly used carbon structural steel. Main features: It has high plasticity, toughness, welding performance, cold stamping performance, as well as certain strength and good cold bending performance. Application examples: Widely used in parts and welded structures with general requirements. Such as tie rods, connecting rods, pins, shafts, screws, nuts, ferrules, brackets, machine bases, building structures, bridges, etc. that are not stressed.

- 3. 40Cr-one of the most widely used steel grades, belongs to alloy structural steel. Main features: After quenching and tempering treatment, it has good comprehensive mechanical properties, low-temperature impact toughness and low notch sensitivity, good hardenability, high fatigue strength when oil-cooled, and easy parts with complex shapes when water-cooled. Cracks occur, cold-formed plasticity is medium, good machinability after tempering or quenching and tempering, but the weldability is not good, and cracks are easy to occur. It should be preheated to 100~150℃ before welding. It is generally used in quenched and tempered state. Carburize carbonitriding and high frequency surface quenching treatment. Application example: After quenching and tempering, it is used to manufacture medium-speed and medium-load parts, such as machine tool gears, shafts, worms, spline shafts, thimble sleeves, etc., after quenching and tempering, and high-frequency surface quenching, it is used to make the surface with high hardness and resistance. Grinding parts, such as gears, shafts, spindles, crankshafts, spindles, sleeves, pins, connecting rods, screws and nuts, intake valves, etc., after quenching and tempering at medium temperature, they are used to manufacture heavy-duty, medium-speed impact Parts, such as oil pump rotors, sliders, gears, spindles, collars, etc., are used to manufacture heavy-duty, low-impact, wear-resistant parts after quenching and low-temperature tempering, such as worms, spindles, shafts, collars, etc., carbon At the nitriding site, transmission parts with larger dimensions and higher low-temperature impact toughness, such as shafts, gears, etc., will be manufactured.

- 4. HT150——Gray cast iron application examples: gear box body, machine bed, box body, hydraulic cylinder, pump body, valve body, flywheel, cylinder head, pulley, bearing cover, etc.

- 5. 35-Commonly used materials for various standard parts and fasteners; main features: proper strength, good plasticity, high cold plasticity, and acceptable weldability. Partial upsetting and drawing can be done in cold conditions. Low hardenability, application examples after normalizing or quenching and tempering: Suitable for manufacturing small cross-section parts, parts that can withstand larger loads: such as crankshafts, levers, connecting rods, hooks and loops, etc., various standard parts, fasteners

- 6. 65Mn-Examples of commonly used spring steel applications: small sizes of various flat and round springs, cushion springs, spring springs, and can also be made into spring rings, valve springs, clutch springs, brake springs, cold-rolled coil springs , Circlips and so on.

- 7. 0Cr18Ni9-the most commonly used stainless steel (American Steel No. 304, Japanese Steel No. SUS304) Features and applications: It is the most widely used as a stainless heat-resistant steel, such as food equipment, general chemical equipment, and industrial equipment.

- 8. Cr12-commonly used cold work die steel (American steel number D3, Japanese steel number SKD1); characteristics and applications: Cr12 steel is a widely used cold work die steel, belonging to the high carbon and high chromium type ledeburite steel. The steel has good hardenability and good wear resistance; because the carbon content of Cr12 steel is as high as 2.3%, it has poor impact toughness, easy brittleness, and easy formation of uneven eutectic carbides; Cr12 steel is due to It has good wear resistance and is mostly used to manufacture cold punches, punches, blanking dies, cold heading dies, punches and dies of cold extrusion dies, drill sleeves, gauges that require high wear resistance with less impact load , Wire drawing die, stamping die, thread rolling board, deep drawing die and cold press die for powder metallurgy, etc.

- 9. DC53-Commonly used Japanese imported cold work die steel characteristics and applications: high strength and toughness cold work die steel, Japanese Datong Special Steel (strain) manufacturer steel grade. After high temperature tempering, it has high hardness, high toughness and good wire cutting performance. Used for precision cold stamping dies, drawing dies, thread rolling dies, cold blanking dies, punches, etc. 10, SM45-ordinary carbon plastic mold steel (Japanese steel number S45C)

- 10. DCCr12MoV-domestically made wear-resistant chromium steel. Compared with Cr12 steel, the carbon content is lower, and the addition of Mo and V, the uneven carbide is improved, MO can reduce carbide segregation and improve hardenability, and V can be refined Grain increases toughness. This steel has high hardenability, the cross section can be completely hardened below 400mm, and it can still maintain good hardness and wear resistance at 300~400℃. It has higher toughness than Cr12, and its volume change is small during quenching. , It also has high wear resistance and good comprehensive mechanical properties. Therefore, it is possible to manufacture various molds with large cross-sections, complex shapes, and withstand greater impact, such as ordinary drawing dies, punching dies, punching dies, blanking dies, Trimming die, hemming die, wire drawing die, cold extrusion die, cold cutting scissors, circular saw, standard tools, measuring tools, etc.

- 11. SKD11-tough chromium steel. Produced by Hitachi, Japan. Technically improves the casting structure in steel and refines the grains. Compared with Cr12mov, the toughness and wear resistance are improved. The service life of the mold is prolonged.

- 12. D2-high carbon and high chromium cold work steel, made in the United States. It has high hardenability, hardenability, wear resistance, high temperature oxidation resistance, good rust resistance after quenching and polishing, and small heat treatment deformation. Manufacture all kinds of cold work dies, tools and measuring tools that require high precision and long life, such as drawing dies, cold extrusion dies, cold shearing knives, etc.

- 13. SKD11 (SLD)-non-deformation and toughness high chromium steel. Produced by Hitachi, Japan. Due to the increase in the content of MO and V in the steel, the casting structure in the steel is improved, the crystal grains are refined, and the carbide morphology is improved. The strength and toughness of this steel (bending strength, deflection, impact toughness, etc.) are higher than SKD1, D2, wear resistance has also increased, and it has higher tempering resistance. Practice has proved that the life of this steel mold is better than that of Cr12mov. Improve. Often manufacturing demanding molds, such as drawing molds, impact grinding wheel molds, etc.

- 14. DC53-high toughness and high chromium steel, produced by Datong Co., Ltd., Japan. The heat treatment hardness is higher than SKD11. After high temperature (520-530) tempering, it can reach high hardness of 62-63HRC. In terms of strength and wear resistance, DC53 exceeds SKD11. Toughness is twice that of SKD11. The toughness of DC53 is rarely cracked and cracked in cold work mold manufacturing. It greatly improves the service life. The residual stress is small. The residual stress is reduced after high temperature. It is obtained by the cracks and deformation after the wire cutting process. Inhibition. Machinability and abrasiveness exceed SKD11. Used for precision stamping dies, cold forging, deep drawing dies, etc.

- 15. SKH-9-general-purpose high-speed steel with high wear resistance and toughness. Produced by Hitachi, Japan. Used for cold forging dies, strip cutters, drills, reamers, punches, etc.

- 16. ASP-23-powder metallurgy high-speed steel, made in Sweden. Carbide distribution is extremely uniform, wear resistance, high toughness, easy to process, heat treatment and dimensional stability. Used for punches, deep drawing dies, drilling dies, milling cutters Various long-life cutting tools such as shear blades.

- 17. P20——Generally required large and small plastic molds, made in the United States. It can be operated by electro-erosion. The factory state is pre-hardened HB270-300. The quenching hardness is HRC52.

- 18. 718-high-demand large and small plastic molds, made in Sweden. Especially for electro-erosion operation. The factory state is pre-hardened HB290-330. Quenching hardness HRC52

- 19. Nak80-high mirror surface, high-precision plastic mold, produced by Datong Co., Ltd., Japan. The factory state is pre-hardened HB370-400. Quenching hardness HRC52

- 20. S136-anti-corrosion and mirror-polished plastic mold, made in Sweden. Pre-hardened HB<215. Quenching hardness HRC52.

- 21. H13-ordinary commonly used die-casting die, used for aluminum, zinc, magnesium and alloy die-casting. Hot stamping die, aluminum extrusion die,

- 22. SKD61-high-grade die-casting mold, produced by Hitachi, Japan, through electric ballast remelting technology, the service life is significantly improved than H13. Hot stamping die, aluminum extrusion die,

- 23. 8407-high-level die-casting die, made in Sweden. Hot stamping die, aluminum extrusion die.

- 24. FDAC-added sulfur to enhance its ease of cutting. The factory pre-hardened hardness is 338-42HRC, which can be directly engraved and processed without quenching and tempering. It is used for small batch molds, simple molds, and various resin products. Sliding parts, short delivery time mold parts. Zipper mold, glasses frame mold.

Please keep the source and address of this article for reprinting:Steel Materials And Characteristics For Common Machining

Minghe Die Casting Company are dedicated to manufacture and provide quality and high performance Casting Parts(metal die casting parts range mainly include Thin-Wall Die Casting,Hot Chamber Die Casting,Cold Chamber Die Casting),Round Service(Die Casting Service,Cnc Machining,Mold Making,Surface Treatment).Any custom Aluminum die casting, magnesium or Zamak/zinc die casting and other castings requirements are welcome to contact us.

Under the control of ISO9001 and TS 16949,All processes are carried out through hundreds of advanced die casting machines, 5-axis machines, and other facilities, ranging from blasters to Ultra Sonic washing machines.Minghe not only has advanced equipment but also have professional team of experienced engineers,operators and inspectors to make the customer’s design come true.

Contract manufacturer of die castings. Capabilities include cold chamber aluminum die casting parts from 0.15 lbs. to 6 lbs., quick change set up, and machining. Value-added services include polishing, vibrating, deburring, shot blasting, painting, plating, coating, assembly, and tooling. Materials worked with include alloys such as 360, 380, 383, and 413.

Zinc die casting design assistance/concurrent engineering services. Custom manufacturer of precision zinc die castings. Miniature castings, high pressure die castings, multi-slide mold castings, conventional mold castings, unit die and independent die castings and cavity sealed castings can be manufactured. Castings can be manufactured in lengths and widths up to 24 in. in +/-0.0005 in. tolerance.

ISO 9001: 2015 certified manufacturer of die cast magnesium, Capabilities include high-pressure magnesium die casting up to 200 ton hot chamber & 3000 ton cold chamber, tooling design, polishing, molding, machining, powder & liquid painting, full QA with CMM capabilities, assembly, packaging & delivery.

ITAF16949 certified. Additional Casting Service Include investment casting,sand casting,Gravity Casting, Lost Foam Casting,Centrifugal Casting,Vacuum Casting,Permanent Mold Casting,.Capabilities include EDI, engineering assistance, solid modeling and secondary processing.

Casting Industries Parts Case Studies for: Cars, Bikes, Aircraft, Musical instruments, Watercraft, Optical devices, Sensors, Models, Electronic devices, Enclosures, Clocks, Machinery, Engines, Furniture, Jewelry, Jigs, Telecom, Lighting, Medical devices, Photographic devices, Robots, Sculptures, Sound equipment, Sporting equipment, Tooling, Toys and more.

What Can we help you do next?

∇ Go To Homepage For Die Casting China

→Casting Parts-Find out what we have done.

→Ralated Tips About Die Casting Services

By Minghe Die Casting Manufacturer |Categories: Helpful Articles |Material Tags: Aluminum Casting, Zinc Casting, Magnesium Casting, Titanium Casting, Stainless Steel Casting, Brass Casting,Bronze Casting,Casting Video,Company History,Aluminum Die Casting |Comments Off