The Control Of Impurity Content In Manganese Iron Alloy

Out-of-furnace refining is an important part of the modern steel production process. The quality of steel depends largely on the out-of-furnace refining process.

The addition of ferroalloy will play a role in deoxidizing and alloying molten steel. Among them, the manganese ferroalloy is the ferroalloy with the largest output, the largest amount and the most versatile.

variety of steel puts forward low phosphorus, low sulfur, low titanium, low aluminum, low nitrogen, low oxygen, low hydrogen and other requirements for manganese iron alloys. The quality of current manganese-based ferroalloys cannot meet the requirements of varieties of steel. The main quality problems that exist are: high content of Ti, Al, P, O, N, and H in ferromanganese alloys; P in medium and low-carbon ferromanganese alloys , S, O, N, H content is high. The control of the content of various impurities in manganese iron alloys should be strengthened, mainly:

1.Gas Content

Since nitrogen reacts quickly with manganese at 800-1000°C, and nitrogen is also increased during the cooling process, increasing the cooling rate is beneficial to reducing nitrogen. Control the H2O content (adsorbed water and crystal water) of the charge and reduce the volatile content of coke, reduce the contact between the alloy and hydrogen in the furnace, and reduce the hydrogen content in the manganese iron alloy. At the same time, avoid contact with moist air in the process of crushing, transportation and storage to prevent hydrogen absorption reaction of the alloy.

2.Carbon, Sulfur And Oxygen Content

The feasible ways to reduce the carbon content in the manganese-silicon ferroalloy are: sedation and carbon reduction; increase the silicon content of the manganese-silicon alloy; synthetic slag refining to reduce carbon.The sulphur content in the manganese iron alloy can be reduced by making alkaline slag and slag washing and refining the alloy.

Through remelting and refining, the oxide inclusions in the manganese iron alloy can float to the surface of the alloy and be adsorbed by the top dross. In addition, the principle and technology of deoxidation in the steelmaking process can be used to deoxidize manganese iron alloys with aluminum and silicon to reduce oxygen content.

3.Aluminum And Titanium Content

Manganese ferrosilicon alloy contains high content of aluminum and titanium, and its control method is to enter the furnace and refining outside the furnace. The method of ferrosilicon refining can be used for reference to the dealuminum and detitanium of manganese ferrosilicon alloy outside the furnace.

4. Control Of Phosphorus Content

The phosphorus content of manganese-based ferroalloys is controlled by reducing the phosphorus in the raw materials and dephosphorizing outside the furnace. There are two methods for reducing phosphorus in raw materials: dephosphorization of manganese ore and smelting of low-phosphorus and rich manganese slag. The process of dephosphorization of manganese ore is complicated, while the process of smelting low-phosphorus and rich manganese slag is longer, and the cost and energy consumption are high. Dephosphorization outside the ferromanganese furnace may be a relatively simple and economically feasible method.

Please keep the source and address of this article for reprinting: The Control Of Impurity Content In Manganese Iron Alloy

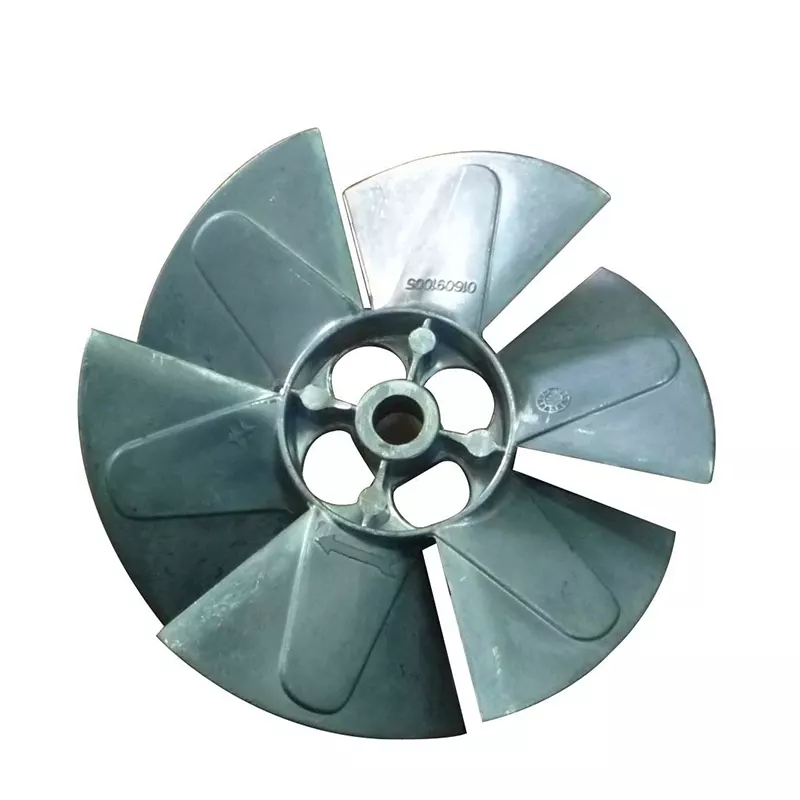

Minghe Die Casting Company are dedicated to manufacture and provide quality and high performance Casting Parts(metal die casting parts range mainly include Thin-Wall Die Casting,Hot Chamber Die Casting,Cold Chamber Die Casting),Round Service(Die Casting Service,Cnc Machining,Mold Making,Surface Treatment).Any custom Aluminum die casting, magnesium or Zamak/zinc die casting and other castings requirements are welcome to contact us.

Under the control of ISO9001 and TS 16949,All processes are carried out through hundreds of advanced die casting machines, 5-axis machines, and other facilities, ranging from blasters to Ultra Sonic washing machines.Minghe not only has advanced equipment but also have professional team of experienced engineers,operators and inspectors to make the customer’s design come true.

Contract manufacturer of die castings. Capabilities include cold chamber aluminum die casting parts from 0.15 lbs. to 6 lbs., quick change set up, and machining. Value-added services include polishing, vibrating, deburring, shot blasting, painting, plating, coating, assembly, and tooling. Materials worked with include alloys such as 360, 380, 383, and 413.

Zinc die casting design assistance/concurrent engineering services. Custom manufacturer of precision zinc die castings. Miniature castings, high pressure die castings, multi-slide mold castings, conventional mold castings, unit die and independent die castings and cavity sealed castings can be manufactured. Castings can be manufactured in lengths and widths up to 24 in. in +/-0.0005 in. tolerance.

ISO 9001: 2015 certified manufacturer of die cast magnesium, Capabilities include high-pressure magnesium die casting up to 200 ton hot chamber & 3000 ton cold chamber, tooling design, polishing, molding, machining, powder & liquid painting, full QA with CMM capabilities, assembly, packaging & delivery.

ITAF16949 certified. Additional Casting Service Include investment casting,sand casting,Gravity Casting, Lost Foam Casting,Centrifugal Casting,Vacuum Casting,Permanent Mold Casting,.Capabilities include EDI, engineering assistance, solid modeling and secondary processing.

Casting Industries Parts Case Studies for: Cars, Bikes, Aircraft, Musical instruments, Watercraft, Optical devices, Sensors, Models, Electronic devices, Enclosures, Clocks, Machinery, Engines, Furniture, Jewelry, Jigs, Telecom, Lighting, Medical devices, Photographic devices, Robots, Sculptures, Sound equipment, Sporting equipment, Tooling, Toys and more.

What Can we help you do next?

∇ Go To Homepage For Die Casting China

→Casting Parts-Find out what we have done.

→Ralated Tips About Die Casting Services

By Minghe Die Casting Manufacturer |Categories: Helpful Articles |Material Tags: Aluminum Casting, Zinc Casting, Magnesium Casting, Titanium Casting, Stainless Steel Casting, Brass Casting,Bronze Casting,Casting Video,Company History,Aluminum Die Casting |Comments Off