The Principles Of Pump Cleaning

Cleaning is an important part of the pump repair work, and the cleaning quality has a great influence on the repair quality of the machinery. The use of correct cleaning methods to improve cleaning quality and reduce costs is one of the issues that repair workers must consider.

Cleaning in repair work includes mechanical external cleaning and parts cleaning. Parts cleaning can be divided into cleaning before appraisal, cleaning before assembly, and cleaning before work preparation before part plating or bonding due to different purposes.

Among the parts cleaning of the water pump, the cleaning requirements of the plated and bonded parts are the highest, and the cleaning quality is not high. It is often the cause of coating or bonding failure, and the cleaning quality of the parts assembly has a great impact on the service life of the machine. Due to the serious failure of the cleaning, a large amount of abrasive infiltrates into the important friction pair or the lubricating oil channel is blocked by dirt. As a result, early mechanical wear and accidental damage often occur in some substandard repair work, which must be paid attention to.

Here are a few cleanings of centrifugal pumps

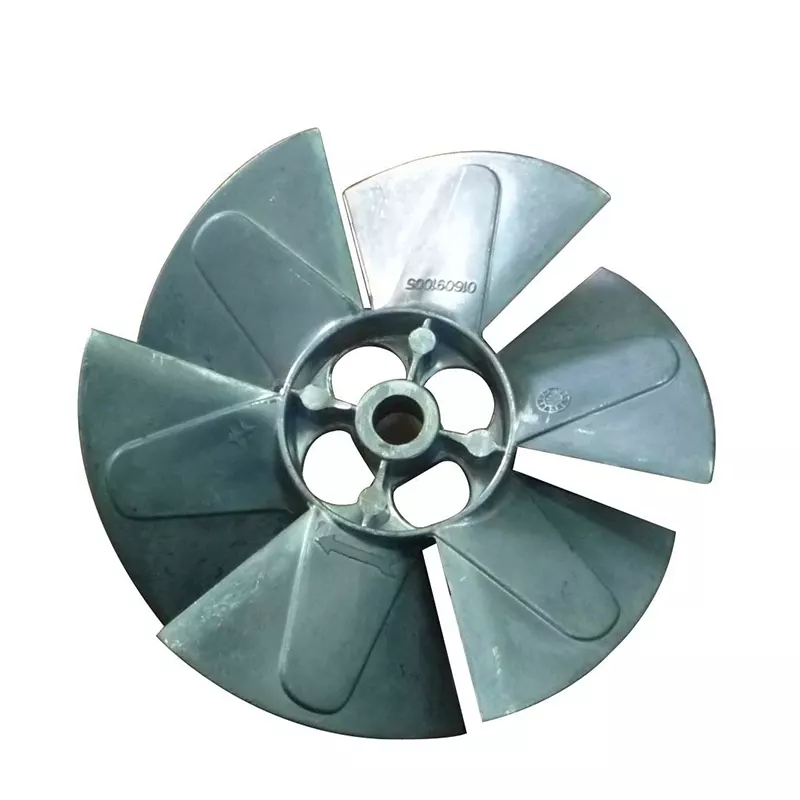

- Scrape off the scale and rust accumulated on the inner and outer surfaces of the impeller, the seal ring and the bearing, etc., and then clean and blow off with water or compressed air.

- Clean the grease and rust accumulated on the joint surfaces of the water pump housing.

- Clean the water seal pipe and check whether the pipe is unblocked.

- Clean the bushes and bearings, remove the grease, and then clean the oil ring and oil level gauge. The ball bearings should be cleaned with gasoline.

- All parts and components not to be assembled temporarily should be protected with oil after cleaning.

Cleaning should follow the following steps

- According to the processing requirements, some parts need to be polished, and the surface must not have processing burrs, etc.;

- All parts are degreased;

- Pickling passivation after degreasing is completed (the cleaning agent does not contain phosphorus);

- Rinse with pure water after pickling and passivation, and there should be no chemical residue (this step is omitted for carbon steel parts);

- Use non-woven cloth to dry the parts one by one, and do not leave the surface of the parts such as wire bristles, or blow dry with clean nitrogen;

- Use non-woven fabric or precision filter paper dipped in analytical pure alcohol to wipe each part until there is no dirty color.

The basic principle of centrifugal pump cleaning is that all cleaning methods must fully consider the following basic requirements:

- Ensure that the requirements for the cleanliness of the parts are met. In repairing the water pump, various parts have different requirements for cleanliness. In assembly, the cleaning requirements of mating parts are higher than non-matching parts, moving parts are higher than static mating parts, and precision matching parts are higher than non-precision matching parts. For the surface of sprayed, plated, and bonded workpieces, the cleaning requirements are very high. When cleaning, different cleaning agents and cleaning methods must be adopted according to different requirements to ensure the required cleaning quality.

- Prevent the corrosion of the parts, and no corrosion of any degree is allowed to the precision parts. When the pump parts need to be parked for a period of time after cleaning, the anti-rust ability of the cleaning fluid or other anti-rust measures should be considered.

- Ensure the safety of operation, prevent fire or poisoning the human body and cause pollution to the environment.

Please keep the source and address of this article for reprinting: The Principles Of Pump Cleaning

Minghe Die Casting Company are dedicated to manufacture and provide quality and high performance Casting Parts(metal die casting parts range mainly include Thin-Wall Die Casting,Hot Chamber Die Casting,Cold Chamber Die Casting),Round Service(Die Casting Service,Cnc Machining,Mold Making,Surface Treatment).Any custom Aluminum die casting, magnesium or Zamak/zinc die casting and other castings requirements are welcome to contact us.

Under the control of ISO9001 and TS 16949,All processes are carried out through hundreds of advanced die casting machines, 5-axis machines, and other facilities, ranging from blasters to Ultra Sonic washing machines.Minghe not only has advanced equipment but also have professional team of experienced engineers,operators and inspectors to make the customer’s design come true.

Contract manufacturer of die castings. Capabilities include cold chamber aluminum die casting parts from 0.15 lbs. to 6 lbs., quick change set up, and machining. Value-added services include polishing, vibrating, deburring, shot blasting, painting, plating, coating, assembly, and tooling. Materials worked with include alloys such as 360, 380, 383, and 413.

Zinc die casting design assistance/concurrent engineering services. Custom manufacturer of precision zinc die castings. Miniature castings, high pressure die castings, multi-slide mold castings, conventional mold castings, unit die and independent die castings and cavity sealed castings can be manufactured. Castings can be manufactured in lengths and widths up to 24 in. in +/-0.0005 in. tolerance.

ISO 9001: 2015 certified manufacturer of die cast magnesium, Capabilities include high-pressure magnesium die casting up to 200 ton hot chamber & 3000 ton cold chamber, tooling design, polishing, molding, machining, powder & liquid painting, full QA with CMM capabilities, assembly, packaging & delivery.

ITAF16949 certified. Additional Casting Service Include investment casting,sand casting,Gravity Casting, Lost Foam Casting,Centrifugal Casting,Vacuum Casting,Permanent Mold Casting,.Capabilities include EDI, engineering assistance, solid modeling and secondary processing.

Casting Industries Parts Case Studies for: Cars, Bikes, Aircraft, Musical instruments, Watercraft, Optical devices, Sensors, Models, Electronic devices, Enclosures, Clocks, Machinery, Engines, Furniture, Jewelry, Jigs, Telecom, Lighting, Medical devices, Photographic devices, Robots, Sculptures, Sound equipment, Sporting equipment, Tooling, Toys and more.

What Can we help you do next?

∇ Go To Homepage For Die Casting China

→Casting Parts-Find out what we have done.

→Ralated Tips About Die Casting Services

By Minghe Die Casting Manufacturer |Categories: Helpful Articles |Material Tags: Aluminum Casting, Zinc Casting, Magnesium Casting, Titanium Casting, Stainless Steel Casting, Brass Casting,Bronze Casting,Casting Video,Company History,Aluminum Die Casting |Comments Off