Kitchenware And Cooker

Kitchenware And Cooker Solutions By Casting &Cnc Machining

IATF 16949 CERTIFIED CAST MANUFACTURING AND CNC MACHINING FOR Kitchenware And Cooker

Cooking utensils mean cooking utensils. With the development of modern technology, the materials used for cooking utensils are constantly changing, mostly iron, aluminum, etc. There are also many types of cooking utensils, including rice cookers, microwave ovens, pressure cookers, pans, etc. .

Among them, carbon steel cookware can be made into a thinner material than rolled or beaten while maintaining high strength. Can be heated by rapid high heat. Carbon steel does not transfer heat as much as other materials, but this is also an advantage of being used as a wok and a paella: when a part of the pot is copper, the other parts are intentionally kept at a different temperature. Like cast iron, the carbon steel pan should be preheated and dried before use. Layer oil (preferably lard) on the surface of the pan and place the pan on the stove to heat it. After a period of time, the surface of the pan will turn black and become non-stick. Carbon steel pans are often used in Chinese woks.

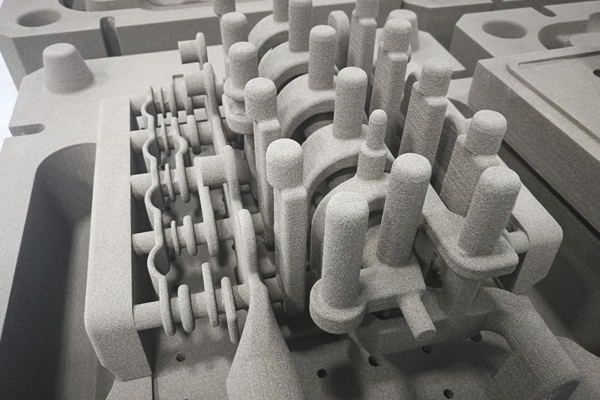

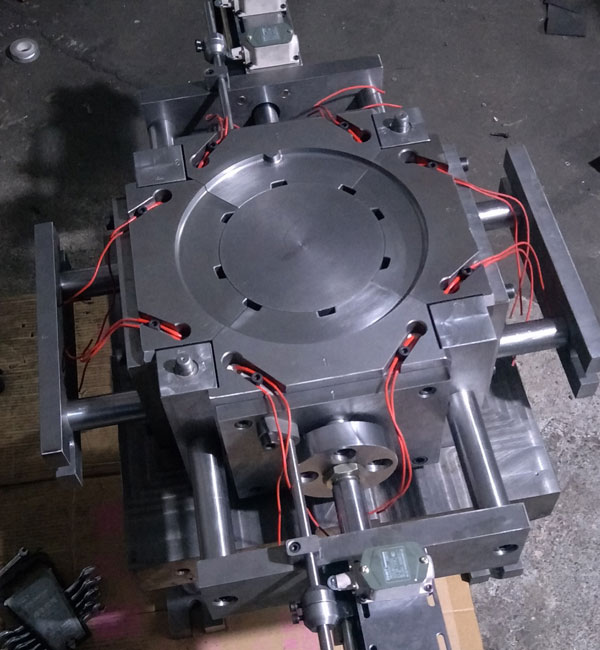

Among them, many cookware or kitchen products require die-casting. The process is relatively complicated. It is necessary to melt the aluminum ingot into aluminum water, and then inject it into the die-casting machine. After the mold is integrated, the pot body has no rivets. Generally, stretched pots and imitation die-casting pots have rivets. This is also an intuitive way to distinguish . Commonly found in European non-stick cookware, the process cost is relatively high, the pot body is thick, the heat is even, and it will not deform. Generally, large factories are capable of producing, and they are mostly used for export.

The use of the highest quality and appropriate materials in the production process, combined with the finish of each article by hand finished, guarantees the high quality of Minghe Die Casting products for a long Due to the exceptional coating, Minghe die-cast cookware is the perfect solution for cooking healthy and dietetic food (without fat) and very easy to clean.

Contact our Kitchenware And Cooker engineer today to discuss the specifics of your complex projects.

1.Commonly Kitchenware And Cooker Applications.

MINGHE’s experience is unrivaled in the design, development, and manufacture of precision die cast and cnc machining solutions for a wide range of Kitchenware And Cooker applications, including but not limited to:

- Casserole

- Saute Pan

- Milk Pan

- Fry Pan

- Grill Pan

- Wok

- Pan Cake

- Multi-Use Pan

- Hamburger Maker

2.Why Choose Us For Your Kitchenware And Cooker Projects

Minghe has over 35 years of experience assisting display cabint manufacturers design cost-effective mechanical components. When you partner with Minghe you can receive the following benefits from our die casting process:

- Minghe’s die casting operation features 40 presses ranging from 250 to 3000 ton. We accommodate some of the most demanding display cabint runs in terms of volume, part size, and complexity. Because of our engineering and modeling capabilities, we are known by our clients as a company that can reduce part complexity, and make the manufacturing process more efficient.

- Minghe can help consolidate your supply chain by offering the complete package of die casting services in addition to engineering support, mold design and troubleshooting, machining, and logistics.

- Minghe is an ISO Certified Die Casting Manufacturer and has extensive experience in designing and manufacturing zinc and aluminum parts to Kitchenware And Cooker quality specifications.

- With presses ranging from large to small, we have the capability to manufacture Kitchenware And Cooker parts of all sizes, from a wok to Hamburger maker for Kitchenware And Cooker Parts.

- We are ITAF 16949 certified and can provide part manufacturing for military and telecom applications.

- Our technology facilitates and streamlines production. Our suite of technology includes AutoCAD, Pro-E, MAGMAsoft®, CAD/CAM and EDI compatibility, and FARO Laser Scanning.

3.Other Manufacturing Service For Custom Kitchenware And Cooker Parts

In addition, Minghe also provides CNC machining, investment casting, sand casting and other services related to customized Kitchenware And Cooker Parts.

| Cnc Machining Kitchenware And Cooker Parts |

| Investment Casting Kitchenware And Cooker Parts |

| Sand Casting Kitchenware And Cooker Parts |

4.Capabilities of Our Precision Manufacturing for Kitchenware And Cooker Parts

In addition, Minghe also provides CNC machining, investment casting, sand casting and other services related to customized Kitchenware And Cooker Parts.

AL360, AL380, AL383, and AL413, ZA-8, ZA-12, ZA-27,Aluminium A356,

Black, White, Silver, Red, Natural, Blue, Green and different colors as client requirements

Sand blasting, shot blasting, polishing, anodizing, oxidation, electrophoresis, chromate, powder coating and painting

Die Casting,Mold Manufacturing,CNC milling, CNC turning, CNC drilling

Hamburger Maker;Multi-Use Pan;

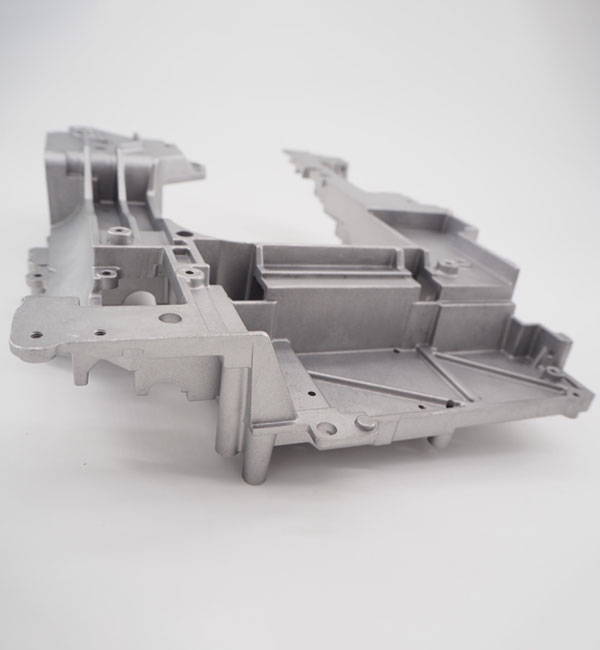

The Minghe Case Studies Of Kitchenware And Cooker Casting Parts

You have a complex part design, Minghe Casting Company can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Minghe Casting ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

Go To View More Casting Parts Cases Studies >>>

Choose the Best Kitchenware And Cooker Casting Service

Currently, our kitchenware and cooker casting parts are exported to America, Canada, Australia, United Kingdom, Germany, France, Sout Africa, and many other countries all over the world. We are ISO9001-2015 registered and also certified by SGS.

Custom china die casting service provides durable and affordable castings that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, marine, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.Contact us or Email sales@hmminghe.com to see how our people, equipment and tooling can bring the best quality for the best price for your kitchenware and cooker cnc machining and casting project.

We Provide Casting Services Include:

Minghe Casting services working with sand casting、metal casting 、investment casting lost foam casting, and more.

Sand Casting

Sand Casting is a traditional casting process that uses sand as the main modeling material to make molds. Gravity casting is generally used for sand molds, and low-pressure casting, centrifugal casting and other processes can also be used when there are special requirements. Sand casting has a wide range of adaptability, small pieces, large pieces, simple pieces, complex pieces, single pieces, and large quantities can be used.

Permanent Mold Casting

Permanent Mold Casting have a long life and high production efficiency, not only have good dimensional accuracy and smooth surface, but also have higher strength than sand castings and are less likely to be damaged when the same molten metal is poured. Therefore, in the mass production of medium and small non-ferrous metal castings, as long as the melting point of the casting material is not too high, metal casting is generally preferred.

Investment Casting

The biggest advantage of investment casting is that because investment castings have high dimensional accuracy and surface finish, they can reduce machining work, but leave a little machining allowance on the parts with higher requirements. It can be seen that the use of investment casting method can save a lot of machine tool equipment and processing man-hours, and greatly save metal raw materials.

Lost Foam Casting

Lost foam casting is to combine paraffin wax or foam models similar to the casting size and shape into model clusters. After brushing and drying refractory coatings, they are buried in dry quartz sand for vibration modeling, and poured under negative pressure to gasify the model. , The liquid metal occupies the position of the model and forms a new casting method after solidification and cooling.

Die Casting

Die casting is a metal casting process, which is characterized by applying high pressure to the molten metal using the cavity of the mold. Molds are usually made of higher-strength alloys, and this process is somewhat similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. Minghe has been China's top die casting service since 1995.

Centrifugal Casting

Centrifugal Casting is a technique and method of injecting liquid metal into a high-speed rotating mold, so that the liquid metal is centrifugal motion to fill the mold and form a casting. Due to the centrifugal movement, the liquid metal can fill the mold well in the radial direction and form the free surface of the casting; it affects the crystallization process of the metal, thereby improving the mechanical and physical properties of the casting.

Low Pressure Casting

Low Pressure Casting means that the mold is generally placed above a sealed crucible, and compressed air is introduced into the crucible to cause a low pressure (0.06~0.15MPa) on the surface of the molten metal, so that the molten metal rises from the riser pipe to fill the mold and control Solidified casting method. This casting method has good feeding and dense structure, easy to cast large thin-walled complex castings, no risers, and a metal recovery rate of 95%. No pollution, easy to realize automation.