Thin Wall Die Casting

What Is Thin-Wall Die Casting?

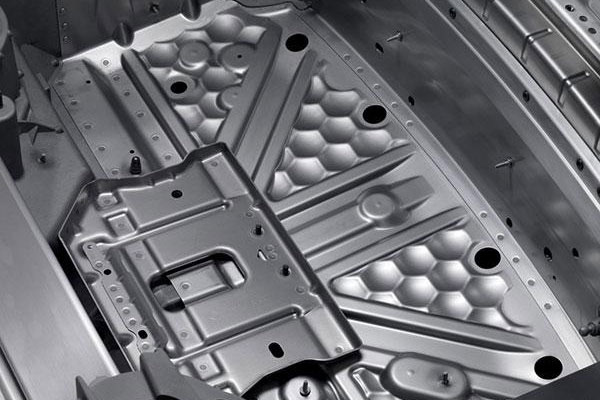

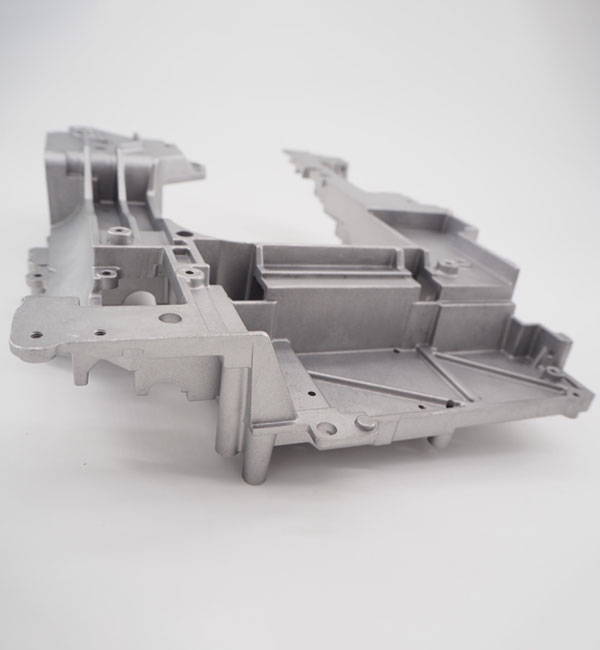

In pursuit of reasonable structure and light weight of parts and components, aerospace, automotive, weapons and other industries have replaced parts that were originally composed of several simple castings, forgings, and machined parts with one integral casting instead. Non-ferrous alloy castings with a wall thickness of 2.0 to 4.0 mm are called thin-walled castings, and aluminum alloy castings with a wall thickness of less than 2.0 mm are called ultra-thin-walled castings. As a fast near-net forming process, die casting has the characteristics of high production efficiency, high dimensional accuracy, and the ability to form thin-walled deep cavity castings with complex shapes and clear contours. It is especially suitable for the integrated design and overall forming of thin-walled complex parts.

In the die-casting production of thin-walled aluminum alloy parts, there are many shortcomings from design to equipment and filling process simulation. More research is needed on the accuracy of alloy, die-casting machine, heat treatment and simulation.

The Thin-walled castings of aluminum alloys with characteristic of light-weighting and good mechanical properties have good prospect in producing large complex structure such as vehicle body and automotive chassis. At Minghe Casting, we provide industry-leading thin wall die casting services for your aluminum part needs

Why Choose Minghe Thin-Wall Die Casting Services?

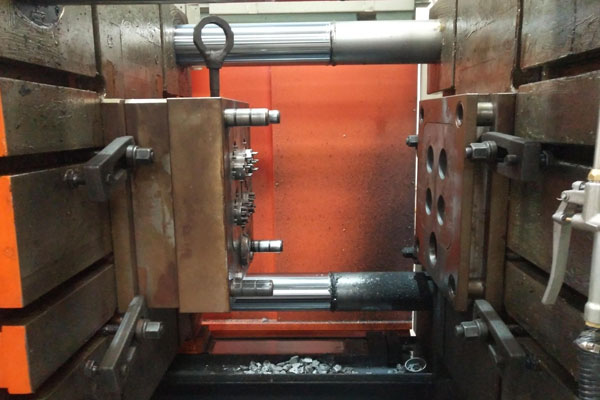

Aluminum alloy thin-wall die castings are mainly used in the body and chassis of high-end automobiles. Figure 1 is the aluminum alloy space frame structure of the Audi A8 car body. The B-pillar is the casting with the largest size, the most complex shape, and the highest mechanical performance requirements.The outer size is about 1 200 mm×200 mm×100 mm, and the wall thickness is 1. .0~2.5mm, Figure 2 is a schematic diagram of its gating system. It can be seen from Figure 2 and Figure 3 that this type of gating system adopts a multi-slit internal gate method, and at the same time uses a vacuum system to assist, requires a mold temperature machine to control the mold temperature, and the casting needs to undergo special heat treatment to meet the final use requirements, but The specific process parameters of vacuum die-casting and heat treatment are kept secret.

At present, only a few companies in China can produce aluminum alloy thin-walled body die castings, such as automobile chassis rear axle beams, car body front longitudinal beams, B-pillars and frame longitudinal frames, etc. More aluminum alloy thin-walled die castings are mainly used in Engine cylinder head cover.

Minghe Casting uses pressure casting to produce qualified ADC12 aluminum cylinder head covers with an average wall thickness of less than 2.5mm,Please contact our die casting experts to help you select the best process to meet the needs of your die casting project, or request a quote on your hot chamber die casting project today.

China Die Casting Services Capabilities

Minghe Casting offers and is capable of producing both medium and long-run projects when providing our die casting services. Minghe Casting has supplied the industry's leading die casting services for more than 35 years in a variety of technology for a wide range of applications.

| Hot Chamber Die Casting |

| Hot Chamber Die Casting for Low Melting Point Alloys.We Can Help with Low Melting Point Alloys |

| Cold Chamber Die Casting |

| Cold Chamber Die Casting for Strong Components and Fast Production |

| Thin Wall Die Casting |

| Ideal Strength-to-Weight Ratio;Thin Wall Die Casting for Lightweight, Complex Aluminum Parts |

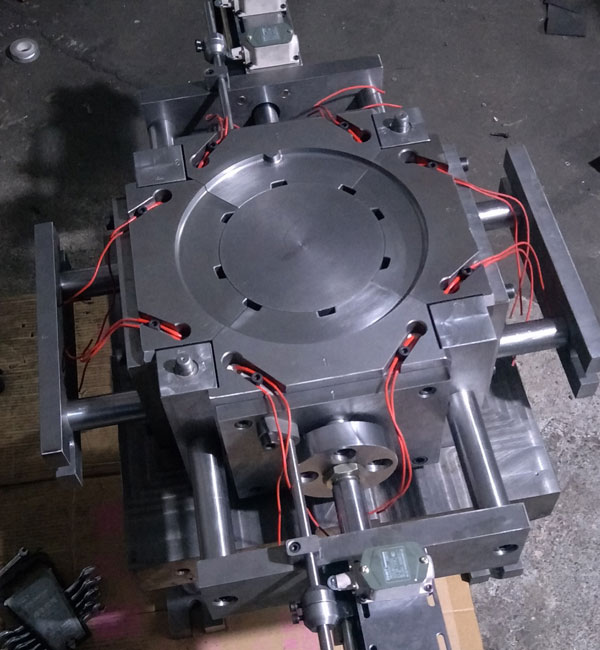

| Mold Manufacturing |

| Die casting molds from Minghe utilize aluminum and zinc alloys to produce small to large run part identical castings. |

| Gravity Casting |

| The method has advantages like cost effective, good quality, and process control over other casting techniques. |

| Cnc Machining |

| Minghe offers in-house CNC machining as a complement to Minghe die casting services. |

China Minghe Die Casting Materials

Minghe Die Casting services working with Aluminum、Zinc and Other.

Aluminum Die Casting

- A360

- A380

- ADC6

- ADC10

- ADC12

- ALSi12

- ALSi9Cu3

Zinc Die Casting

- Zamak3

- Zamak5

- Zamak8

- Zamak12

Magnesium Die Casting

- AM50A

- AM60B

- AZ91D

- AZ63A

Other Casting Material

- Titanium

- Copper

- Bronze

- Steel

- Stainless Steel

- Foundry Iron

Applications of MINGHE Die Casting Services

Die Casting parts are all around you, they may be important components of your car and also can perform vital functions in your electrical equipment. Minghe is an accomplished casting supplier that engaged in a broad range of die casting applications.

Our manufacturing parts are suitable for following industries:

|

AUTOMOTIVE INDUSTRY |

|

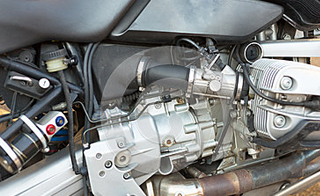

MOTORCYCLE INDUSTRY |

|

MACHINERY INDUSTRY |

|

LED LIGHTING INDUSTRY |

|

HEATSINK INDUSTRY |

|

KITCHENWARE INDUSTRY |

|

PUMP VALVE INDUSTRY |

|

MEDICAL DEVICE INDUSTRY |

|

TELECOM INDUSTRY |

|

BICYCLE INDUSTRY |

|

AEROSPACE INDUSTRY |

|

ELECTRONIC INDUSTRY |

|

DISPLAY CABINT INDUSTRY |

|

ROBOTS INDUSTRY |

|

MORE INDUSTRY |

The Advantages of Minghe Thin Wall Die Cast

- The complex shapes of parts can be obtained and the performance of parts can be improved. Besides, assembly work is reduced.

- Durable and dimensionally stable die casting parts can be obtained with specified shapes, so no machining or less machining is required.

- Die casting parts can have many finishing techniques and surfaces. The process is capable of achieving smooth or textured part surfaces.

- Net shape part configuration is achievable.

- High dimensional accuracy is achievable.

- Fast production.

- Thinner walls are achievable when compared to investment casting.

- Wide range of possible shapes.

- External threads can be cast.

- Holes can be cored to internal tap drill size.

The Minghe Case Studies Of Thin Wall Die Casting

You have a complex part design, Minghe Casting Company can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Minghe Casting ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

Go To View More Casting Parts Cases Studies >>>

Choose The Best Thin Wall Die Casting Service

Currently, our thin wall die casting parts are exported to America, Canada, Australia, United Kingdom, Germany, France, Sout Africa, and many other countries all over the world. We are ISO9001-2015 registered and also certified by SGS.

Custom china die casting service provides durable and affordable castings that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, marine, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.Contact us or Email sales@hmminghe.com to see how our people, equipment and tooling can bring the best quality for the best price for your thin wall die casting project.

We Provide Casting Services Include:

Minghe Casting services working with sand casting、metal casting 、investment casting lost foam casting, and more.

Sand Casting

Sand Casting is a traditional casting process that uses sand as the main modeling material to make molds. Gravity casting is generally used for sand molds, and low-pressure casting, centrifugal casting and other processes can also be used when there are special requirements. Sand casting has a wide range of adaptability, small pieces, large pieces, simple pieces, complex pieces, single pieces, and large quantities can be used.

Permanent Mold Casting

Permanent Mold Casting have a long life and high production efficiency, not only have good dimensional accuracy and smooth surface, but also have higher strength than sand castings and are less likely to be damaged when the same molten metal is poured. Therefore, in the mass production of medium and small non-ferrous metal castings, as long as the melting point of the casting material is not too high, metal casting is generally preferred.

Investment Casting

The biggest advantage of investment casting is that because investment castings have high dimensional accuracy and surface finish, they can reduce machining work, but leave a little machining allowance on the parts with higher requirements. It can be seen that the use of investment casting method can save a lot of machine tool equipment and processing man-hours, and greatly save metal raw materials.

Lost Foam Casting

Lost foam casting is to combine paraffin wax or foam models similar to the casting size and shape into model clusters. After brushing and drying refractory coatings, they are buried in dry quartz sand for vibration modeling, and poured under negative pressure to gasify the model. , The liquid metal occupies the position of the model and forms a new casting method after solidification and cooling.

Die Casting

Die casting is a metal casting process, which is characterized by applying high pressure to the molten metal using the cavity of the mold. Molds are usually made of higher-strength alloys, and this process is somewhat similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. Minghe has been China's top die casting service since 1995.

Centrifugal Casting

Centrifugal Casting is a technique and method of injecting liquid metal into a high-speed rotating mold, so that the liquid metal is centrifugal motion to fill the mold and form a casting. Due to the centrifugal movement, the liquid metal can fill the mold well in the radial direction and form the free surface of the casting; it affects the crystallization process of the metal, thereby improving the mechanical and physical properties of the casting.

Low Pressure Casting

Low Pressure Casting means that the mold is generally placed above a sealed crucible, and compressed air is introduced into the crucible to cause a low pressure (0.06~0.15MPa) on the surface of the molten metal, so that the molten metal rises from the riser pipe to fill the mold and control Solidified casting method. This casting method has good feeding and dense structure, easy to cast large thin-walled complex castings, no risers, and a metal recovery rate of 95%. No pollution, easy to realize automation.