Vacuum Casting

What is Vacuum Casting

Vacuum Casting is a casting process in which metal is smelted, poured and crystallized in a vacuum chamber. Vacuum casting can minimize the gas content in the metal and prevent metal oxidation. This method can produce very demanding special alloy steel castings and extremely easily oxidized titanium alloy castings. Vacuum casting is expensive, and is generally used to smelt alloys and high-quality castings with high vapor pressure and easy volatilization loss. The mold should not contain volatiles.

Vacuum casting is generally divided into two forms:

- vacuum suction casting

- vacuum die casting.

The principle of vacuum casting is to use a plastic film to seal the sand box, and use a vacuum pump to extract the air inside the mold to form a pressure difference between the inside and outside of the mold, so that the dry sand is compacted to form the required cavity. The biggest advantage of V method casting which is different from traditional sand casting is that it does not use adhesives, thus reducing the work of sand processing, and the labor amount of modeling and casting sticky sand cleaning is greatly reduced, and the recovery rate of old sand can reach more than 95%.

The castings produced by the vacuum casting process are of good quality, smooth surface, clear outline, accurate size, uniform hardness, and effectively extend the service life of the castings

If you want to find a cost-effective and rapid vacuum casting solution for your manufacturing needs, Minghe can be a good choice for you. Based on extensive experiences and professional expertise, our vacuum casting fabrication services are available for both prototypes and low to high volume production runs. Working with Minghe, the most advanced fabrication machinery allows us to fabricate end-use vacuum casting parts and products in high efficiency while maintaining premium quality, which saves money and time for our clients significantly. A wide range of materials and surface finishes enable us to make the best option for your project, the raw materials including but not limited to stainless steel, aluminum, brass, copper, steel, plastic, etc. Polishing, painting, sandblasting, plating, anodizing, powder coating and more finishing services bring better surface quality for your parts. Our custom vacuum casting fabrication service provides durable and affordable vacuum casting components that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, marine, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.

The Process Of Vacuum Casting

- - Model: Put the pattern on a hollow mold plate. There are a lot of vent holes on the pattern. When the vacuum is applied, these holes help to make the plastic film tightly adhere to the pattern.

- - Film heating: The plastic film with high stretch rate and high plastic deformation rate is heated and softened by a heater. The heating temperature is generally between 80 and 120°C.

- - Film forming: Cover the softened film on the surface of the model, through the air hole, under the vacuum suction force of 200 ~ 400mmHg, make the film close to the surface of the model.

- - Put the sand box: After spraying the paint and drying (the process does not need to be), put the special sand box on the model covered with the film.

- - Sanding and tapping: Add dry sand with a good filling efficiency and a particle size of 100-200 mesh into the sand box, and then perform micro-vibration to make the sand compact to a higher density.

- - Cover mold: Open the sprue cup, smooth the surface of the sand layer, and cover with plastic film to close the sand box.

- - Mold ejection: the flask is evacuated and the mold is hardened under the action of atmospheric pressure with the help of the film covering the surface of the flask. When the mold is ejected, the vacuum of the negative pressure box is released to release the adsorption force of the template to the film, and then the top box is ejected to complete a mold.

- - Closed box pouring: Before closing the box, the core and cold iron can be lowered according to the process requirements, and the upper and lower boxes can be combined to form a casting mold with a pouring riser and a cavity, which is poured in a vacuum state.

- - Out of the box and falling sand: After a suitable cooling time, the vacuum is cancelled and the normal pressure is restored, so that the free flowing sand flows out, and a clean casting without sand lump and mechanical sand is saved. The sand can be used again after cooling.

Different Types Production Scenario Of Vacuum Casting

Minghe always adheres to the customer's requirements and the company's service standards. In any link of mold design, mold assembly, mold debugging, mold trial production, casting process, etc., there are dedicated engineers to keep you on the phone;

| 1.Model▶ |

| 2.Film-Heating ▶ |

| 3.Film Forming ▶ |

| 4.Put the Sand Box▶ |

| 5.Drawing▶ |

| 6.Shaking Off The Box▶ |

| 7.Boiler ▶ |

| 8.Foaming Machine▶ |

| 9.Intelligent Continuous Casting▶ |

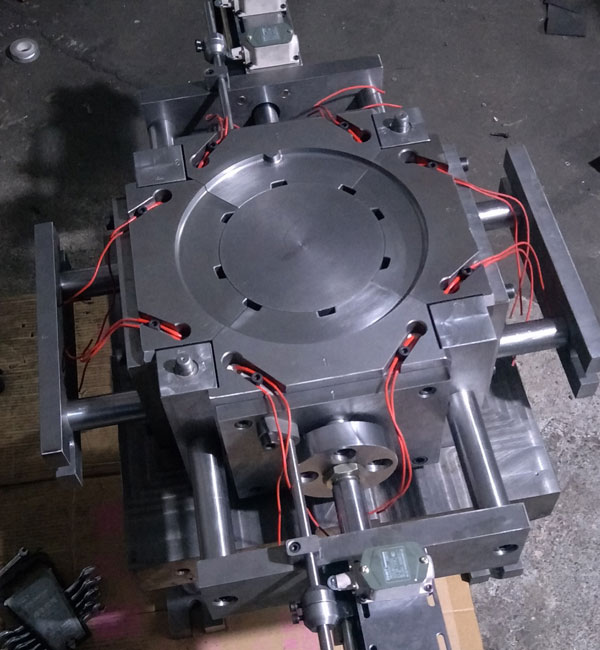

| 10.Vacuum Casting Machine▶ |

| 11.Vacuum Casting Machine▶ |

| 12.Vacuum System▶ |

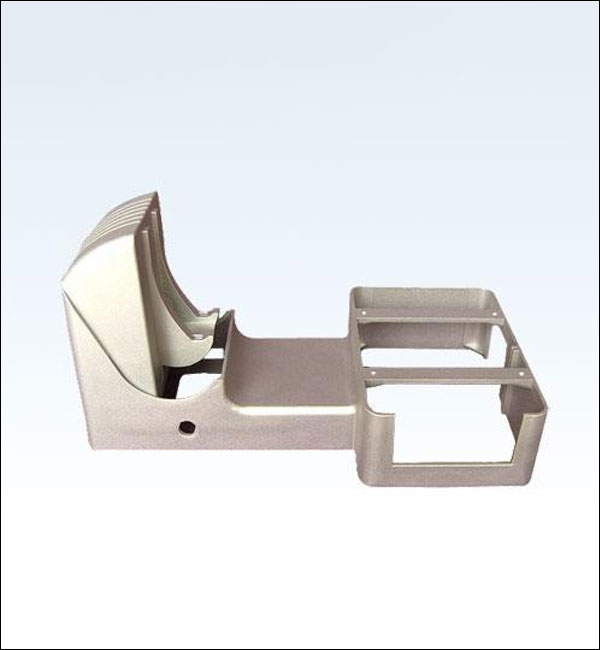

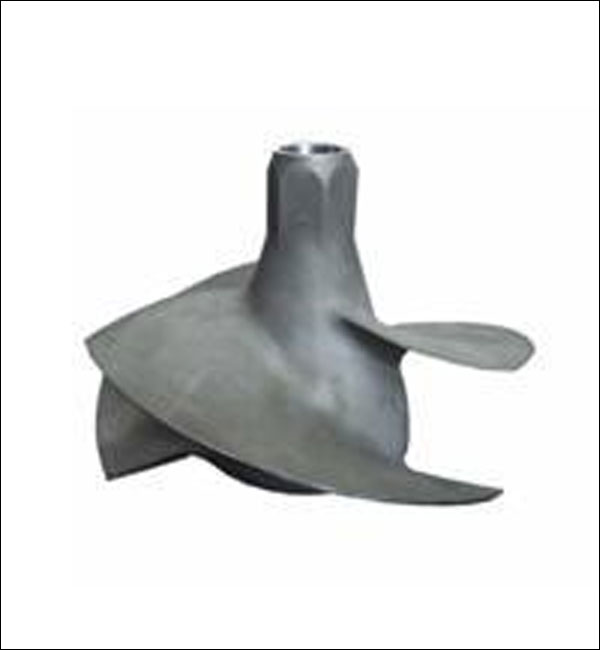

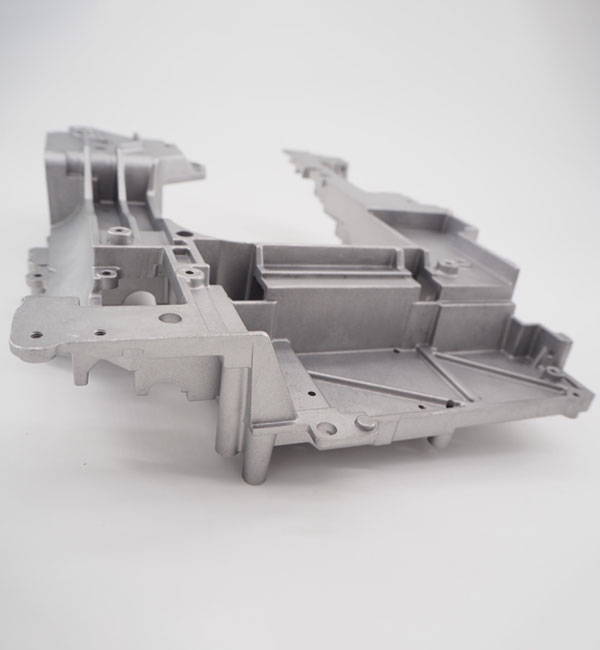

The Minghe Case Studies Of Vacuum Casting

Minghe Casting fabrication services are available for both design to reality and low to high volume production runs of your die casting parts,sand casting parts,investment casting parts,metal casting parts, lost foam casting parts and more.

Go To View More Casting Parts Cases Studies >>>

Choose the Best Vacuum Casting Supplier

Currently, our vacuum casting parts are exported to America, Canada, Australia, United Kingdom, Germany, France, Sout Africa, and many other countries all over the world. We are ISO9001-2015 registered and also certified by SGS.

Our custom vacuum casting fabrication service provides durable and affordable castings that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, marine, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.Contact us or Email sales@hmminghe.com to see how our people, equipment and tooling can bring the best quality for the best price for your vacuum casting project.

We Provide Casting Services Include:

Minghe Casting services working with sand casting、metal casting 、investment casting lost foam casting, and more.

Sand Casting

Sand Casting is a traditional casting process that uses sand as the main modeling material to make molds. Gravity casting is generally used for sand molds, and low-pressure casting, centrifugal casting and other processes can also be used when there are special requirements. Sand casting has a wide range of adaptability, small pieces, large pieces, simple pieces, complex pieces, single pieces, and large quantities can be used.

Permanent Mold Casting

Permanent Mold Casting have a long life and high production efficiency, not only have good dimensional accuracy and smooth surface, but also have higher strength than sand castings and are less likely to be damaged when the same molten metal is poured. Therefore, in the mass production of medium and small non-ferrous metal castings, as long as the melting point of the casting material is not too high, metal casting is generally preferred.

Investment Casting

The biggest advantage of investment casting is that because investment castings have high dimensional accuracy and surface finish, they can reduce machining work, but leave a little machining allowance on the parts with higher requirements. It can be seen that the use of investment casting method can save a lot of machine tool equipment and processing man-hours, and greatly save metal raw materials.

Lost Foam Casting

Lost foam casting is to combine paraffin wax or foam models similar to the casting size and shape into model clusters. After brushing and drying refractory coatings, they are buried in dry quartz sand for vibration modeling, and poured under negative pressure to gasify the model. , The liquid metal occupies the position of the model and forms a new casting method after solidification and cooling.

Die Casting

Die casting is a metal casting process, which is characterized by applying high pressure to the molten metal using the cavity of the mold. Molds are usually made of higher-strength alloys, and this process is somewhat similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. Minghe has been China's top die casting service since 1995.

Centrifugal Casting

Centrifugal Casting is a technique and method of injecting liquid metal into a high-speed rotating mold, so that the liquid metal is centrifugal motion to fill the mold and form a casting. Due to the centrifugal movement, the liquid metal can fill the mold well in the radial direction and form the free surface of the casting; it affects the crystallization process of the metal, thereby improving the mechanical and physical properties of the casting.

Low Pressure Casting

Low Pressure Casting means that the mold is generally placed above a sealed crucible, and compressed air is introduced into the crucible to cause a low pressure (0.06~0.15MPa) on the surface of the molten metal, so that the molten metal rises from the riser pipe to fill the mold and control Solidified casting method. This casting method has good feeding and dense structure, easy to cast large thin-walled complex castings, no risers, and a metal recovery rate of 95%. No pollution, easy to realize automation.